By BILL BREGAR

A major plant expansion has freed up space for additional offices and a training area at General Plastics Inc. in Milwaukee, and it’s right on time, since the Milwaukee industrial thermoformer is adding people to key new positions.

Plant Manager Patrick Cain said the 76-employee General Plastics is beefing up its skill sets and getting more organized as it wins new customers. Some of them are large companies.

“For them to even consider you, you have to be qualified,” Cain said.

In January, General Plastics opened 11,000 square feet of office space. Only about 1,000 square feet of that was existing offices. The rest was in former factory space that became available when the thermoformer added 42,000 square feet onto its plant, doubling the company’s manufacturing space in 2016.

The manufacturing expansion also allowed the company to add a dedicated training area, expand the size of its quality laboratory, mold maintenance shop and fixture room, and improve the lunch room, Cain said.

General Plastics doubled production space with the addition, a $4 million investment. The company also reorganized production after the plant expansion, moving equipment to improve lean manufacturing, he said.

“We doubled the size of the manufacturing space but we actually reduced the total distance the part travels,” Cain said. The company also eliminated an off-site warehouse and brought that in-house.

“We’re revamping our product launch process,” Cain said. The company also is adding “swim lanes” and reduced the total distance parts travel through the shop. The Wisconsin Manufacturing Extension Partnership sent a consultant in to help, and bring in a fresh set of eyes, he said.

General Plastics won a Sustainable Business Award from the Wisconsin Sustainable Business Council for the plant expansion, which included energy efficient lighting and other environmental improvements.

General Plastics runs some of the industry’s largest forming machinery. Key markets include transportation, construction, agriculture, point-of-purchase display, medical and dunnage.

New hires include an additional customer service representative, a product launch person, a thermoforming process engineer, a newly created position of continual improvement supervisor, and a production manager.

The company is now hiring a maintenance supervisor to oversee its three-person maintenance/tooling department.

As plant manager, Cain was handling some of duties, but now the supervisors will report directly to the new production manager on a daily basis. Cain will have them report to him weekly. Cain’s title remains the same, but he’s getting more involved with customers and overall strategy as General Plastics grows and gets new customers.

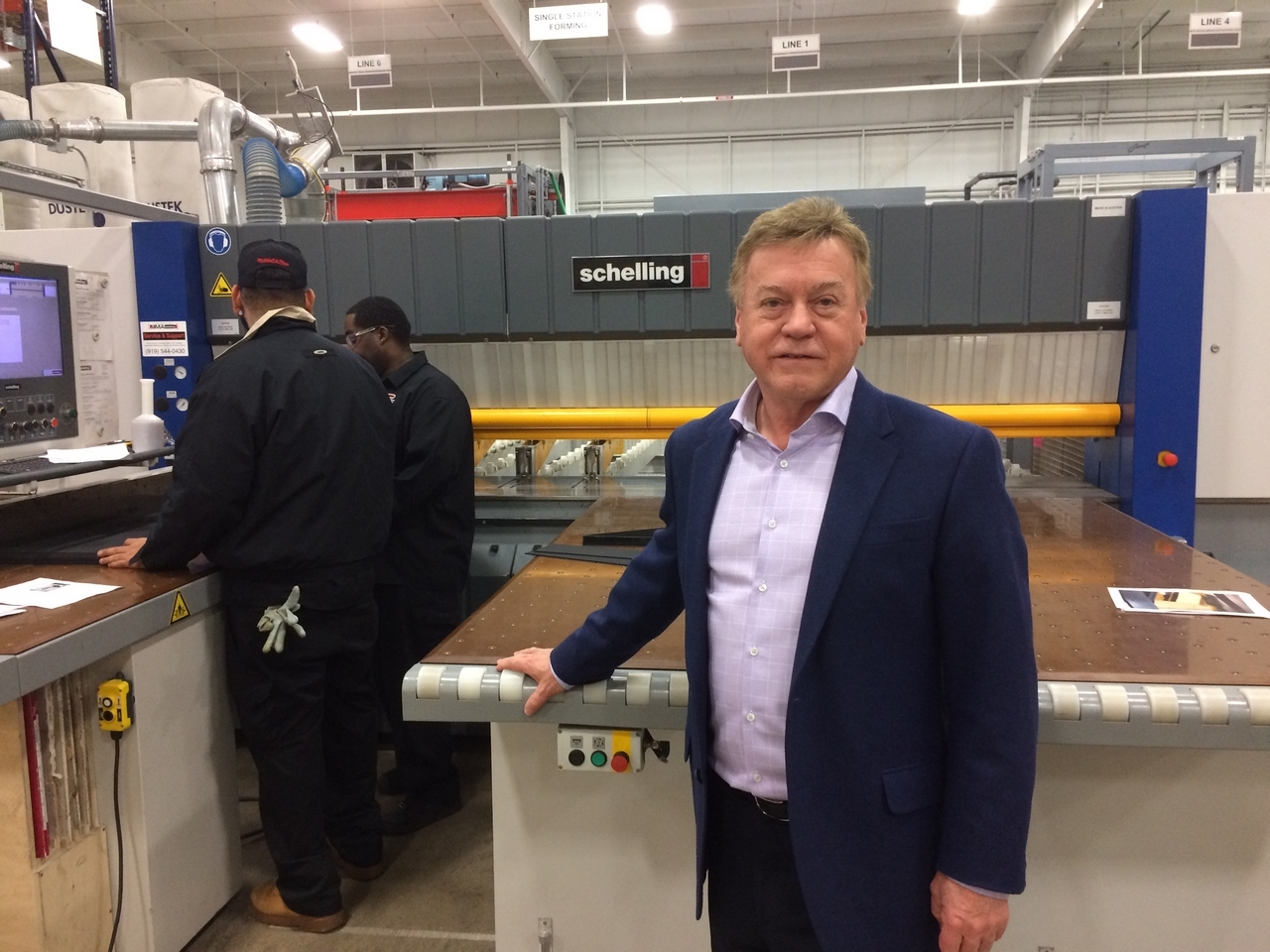

General Plastics President Robert Porsche said the company is getting Cain into a position of longer-term vision “rather than looking at day-to-day crisis management.”

Cain said that bigger customers, especially, do a lot more auditing of suppliers. “A lot of my time was getting pulled away from the shop floor. So part of it was the strategy of getting me more directly involved with the growth plan, and the customers,” he said.

Porsche said Crain is involved in ISO and other certifications, so he’s in a good position to work with larger customers.

General Plastics also added a human resources person, after mainly using temporary services to find new full-time employees. Wisconsin’s unemployment rate has fallen below 3 percent, among the lowest in the country.

“It’s just becoming more and more challenging to find good people,” Cain said.

Since the plant expansion, General Plastics has added a dual-table robotic trimming station and a single-station thermoformer. The company now has 11 pressure forming and vacuum forming machines: eight single-stations and three rotary machines.

Porsche said the company is adding another CNC trimming machine later this year.

In May General Plastics added a granulator to size-reduce trim scrap, which is sent back to a sheet extruder. “We get more for our trim that way and there’s a lot less trucks going back and forth, freight-cost wise,” Cain said.

Meanwhile Porsche is looking forward to the Society of Plastics Engineers’ Thermoforming Conference, scheduled for Sept. 24-26 in Fort Worth, Texas. He will be honored as Thermoformer of the Year — for the second year in a row. The 2017 conference, which was set for Orlando, had to be canceled when Hurricane Irma pounded Florida — so Porsche has had to wait a year before getting the top award.

Follow Us!